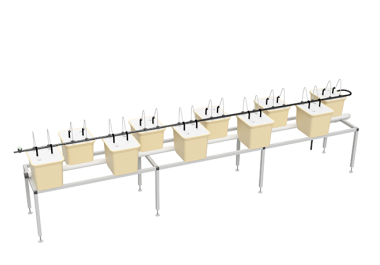

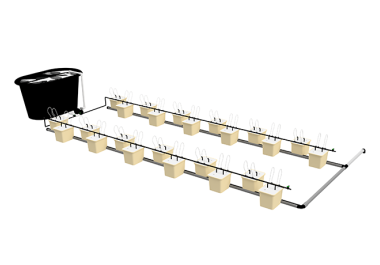

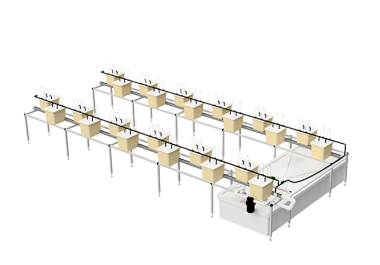

Bato Bucket Systems

Commercial

Explore our Commercial products

We’re Here to Help

If you don’t find the answers to your questions on our website, please contact us and we will be more than happy to assist you. The CropKing team of horticulturists and technical experts is available, whether you’re looking to learn more about hydroponics or need greenhouse equipment or growing supplies.

Join Our Mailing List

Get news, updates, and special promotions in your inbox.